Home »

Blogs

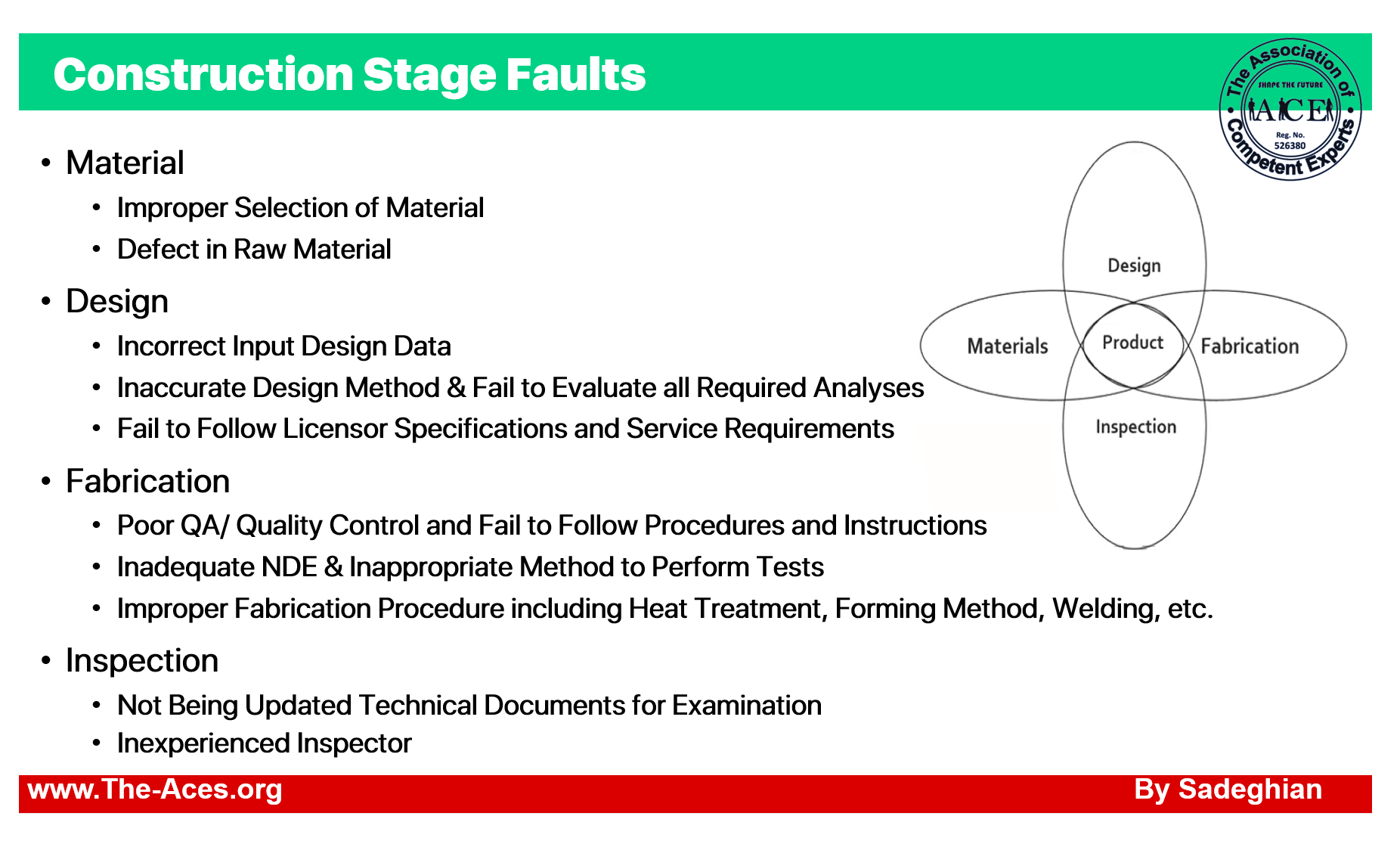

Construction Stage Faults

The mere fact that Designer has proceeded her/his job in a good manner hardly suffices to infer the equipment will be working safely. [...]

More DetailsWhat is the minimum distance to be maintained between two welds in a pipe?

Ans.: The rule of thumb is that the minimum distance between adjacent butt welds is 1 x D. If not, it is never closer than 1-1/2″. This is supposedly to prevent the overlap of HAZ s. Minimum spacing of circumferential welds between centerlines shall not be less than 4 [...]

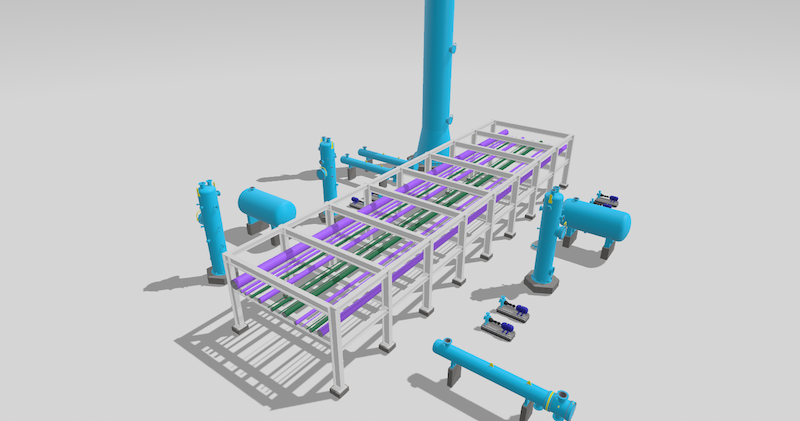

More DetailsHow to Calculate the Width of Pipe Rack?

Ans.: The following formula can be used as a thumb rule: W= (1+B) x (F x N x S + A) Where: F: Safety Factor = 1.5 If pipes are counted from PFD. = 2 If pipes are counted from P&ID. N: number of lines [...]

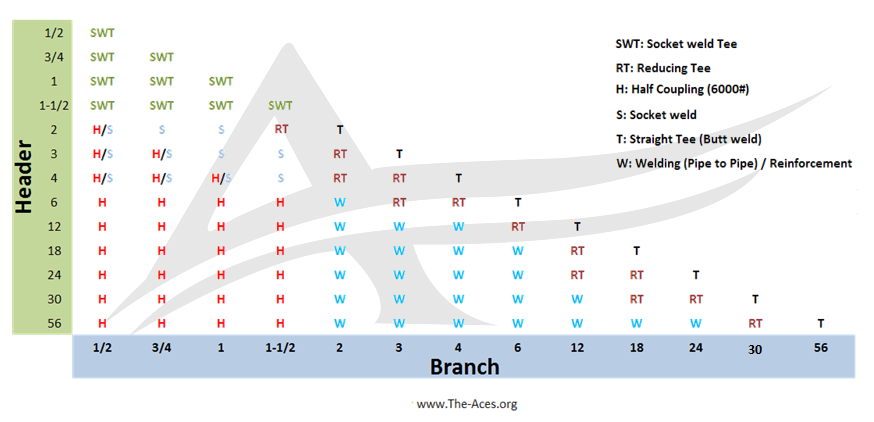

More DetailsHeader Size and Branch type Recommendation

This table shows the branch and header recommendation. [...]

More DetailsProtected: “Analyze” and “Brn. & Young Analyze” Shall be Used Simultaneously for Skirt Design?

There is no excerpt because this is a protected post. [...]

More DetailsFailure Modes of Base Plate

The following figures represent failure modes of base plates: You check which one? [...]

More DetailsSupport Types of Vessels

1- Vertical Equipment Leg: Application: Small vertical drums to very large vessels and spheres up to 80 feet in diameter such as Spherical Pressurized Storage Tanks The maximum ratio of support leg length to drum diameter is typically 2:1. Cross bracing between the legs is typically used to [...]

More DetailsSUBSCRIBE UPDATE ITS FREE