Engineering and Consulting Services: Fitness For Service Assessment

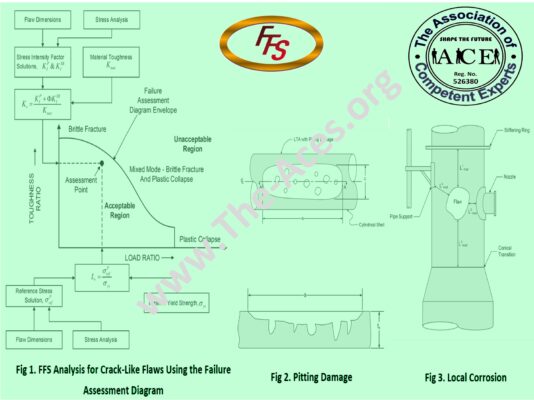

Fitness for Service is a recommended practice approach which describes standardized techniques for pressurized components to determine whether a damaged component- component having flaw- is fit to continue until the next inspection period. ACE offers its own FFS services based on API 579-1/ ASME FFS-1 standard developed to provide guidance for conducting FFS assessments of flaws commonly encountered in the refining and petrochemical industry that occur in pressure vessels, piping, and tankages. However, the assessment procedures in this standard have been used to evaluate flaws encountered in other industries such as the pulp and paper industry, fossil electric power industry, and nuclear industry. The scope of services is as follows. It is worthwhile mentioning that the following services normally will be conducted based on Level 1, Level 2, and Level 3 assessments.

-

Assessment of General Metal Loss

-

Assessment of Local thin Area

-

Assessment of Pitting Corrosion

-

Assessment of Hydrogen Blisters and Hydrogen Damage

-

Assessment of Weld Misalignment and Shell Distortions in Construction Stage

-

Assessment of Dents, Gouges, and Dent-Gouge Combinations

-

Assessment of Laminations of Plates

-

Assessment of Existing Equipment For Brittle Fracture

- Leak Before Break Analysis

To sum up, the following items will be reported based on the above-mentioned assessments:

- Gives permission to continue the service

-

Determines the remaining life of the damaged equipment

-

Provide timetable and set inspection periods

-

Provide ways to prevent and/ or arrest flaw

-

Provides remediation methods

APPLICATIONS

-

Reassessing Existing Plant (Oil, Gas, Petrochemical, and Thermal Power Plants)

- Rerating Components

SOFTWARE

- Based on existent FFS Spreadsheets

- ABAQUS (For Level 3 Assessment)