Engineering and Consulting Services: Piping Vibration Analysis

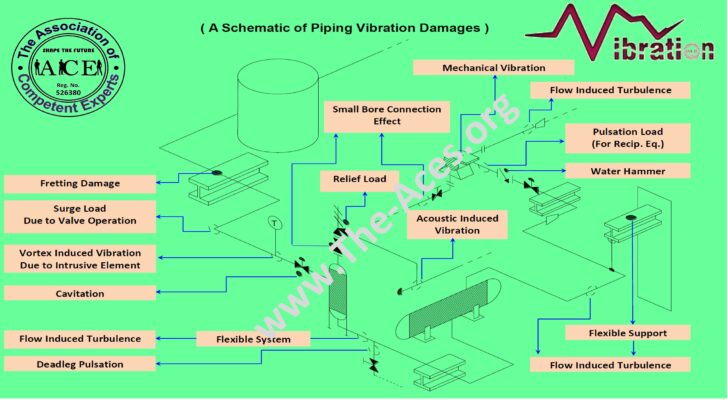

Piping vibration induced fatigue and failures have been recognized in industry as an issue for decades. Despite this, most standards and guidelines (e.g. Piping code ASME B31.1, ASME B31.3, etc.) provide little detail on how to mitigate vibration risks. We will try to fill this knowledge gap.

New methodologies technically utilized to design and assess vibration of pipework in oil, gas, and petrochemical industries, and also thermal power plants during various stages of a project, as defined below. To prevent from irreparable damages, to decrease cost resulting from maintenance and unit outage period, to implement preventive actions for risk of vibrations, and to control the risk and probable problems in the design of piping system are services supplied by ACE. Moreover, inspection techniques, preventative methods and techniques, practical corrective actions, and tips and tricks on piping vibration will be conducted by ACE. The scope of services is as follows:

- Solving Pulsation and Vibration Problems of Piping

- Establish Assessment Methods in field for Piping Vibration

- Piping Flow Induced Turbulence Analysis

- Piping Acoustic Induced Vibration Analysis

- Piping Flow Induced Pulsation Analysis

-

Pulsation Analysis in Piping of Compressors and Pumps (Based on API 618 & API 674) along with mechanical analysis

-

Compressor and Pump Simulation for Piping Vibration Analysis

- Vortex Induced Vibration Analysis

-

Transient and Surge Analyses including Pumps Startup & Shutdown, Valve Opening & Closing (Refer to the “Transient Loads and Pressure Surge Analyses” service)

- Intrusive Pipe Elements Design

- Failure Analysis of Small Bore Connections

- Valve Vibration Evaluation

- Calculation of Stresses Resulting from Piping Excitation

- Nuclear Piping Vibration Analysis (Module Developed by ACE)

- Evaluation of Dynamic Load Effects per B31.1 & B31.3

-

Piping Vibration Analysis with Pi-Vi Assessment Tool (Developed by ACE Co.)

-

Prevention of Vibration Induced Failures in Pipework and Corrective Actions

-

Carrying out Measurements on Piping and Vibration Evaluation of Piping in an Existing Plant

-

Design Practice and Tips and Tricks to Mitigate Vibration Risks

- Piping vibration Inspection

APPLICATIONS

-

New Designs (Oil, Gas, Petrochemical, and Thermal Power Plants)

- Design Stage

- Construction Stage

- Commissioning and Operation Stage

- Reassessing Existing Plant due to

- Changes Made in Plant

- Poor Design

- Poor Construction

- Poor Operation, Monitoring, and Inspection

- Rerating Piping System

SOFTWARE

- Pi-Vi Assessment Tool

- ABAQUS